Description

Combine Harvester Shifter Product Introduction

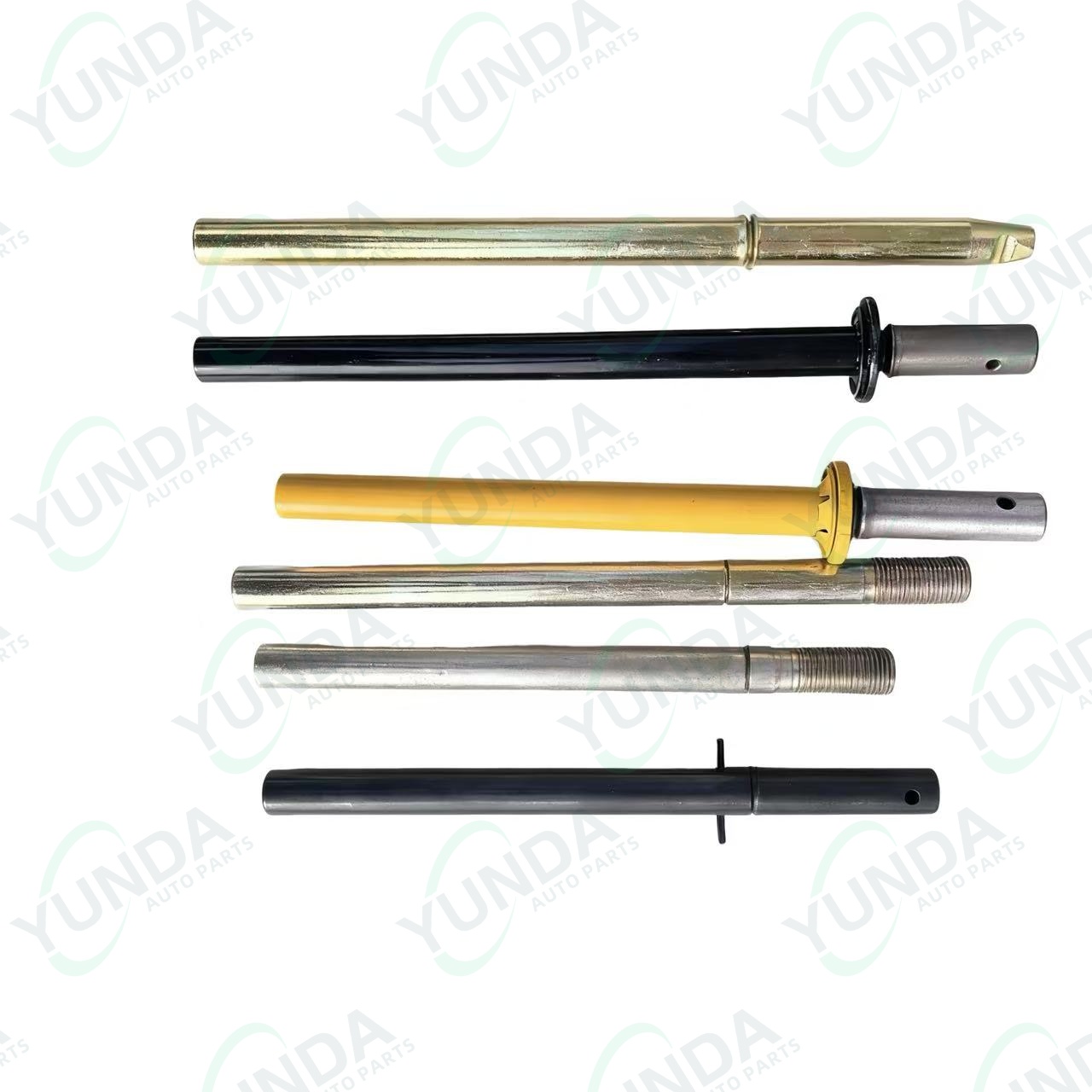

I. Product Overview

The combine harvester shifter is a critical, consumable part on the reel, a core component of the combine harvester. It is typically mounted in rows on the reel and moves as the reel rotates. Its primary function is to guide crop stalks in an orderly manner toward the cutter during harvesting and assist in guiding the cut heads toward the conveyor. Its performance directly impacts harvesting efficiency, header loss rate (ear and grain drop), and overall harvesting quality.

II. Core Functions and Applications

1. Grain Support: Before cutting, it straightens out tangled, fallen, or messy crop stalks, guiding them in an orderly manner toward the cutter, ensuring a clean and efficient cut.

2. Cutting Guidance: While supporting the crop, it stabilizes the crop stalks in the proper cutting position, creating optimal working conditions for the cutter. 3. Material Delivery: After the crop is cut, the cut crop heads are smoothly and continuously delivered to the conveyor chain rake or auger on the header, ensuring smooth material delivery and preventing blockage.

4. Header Cleaning: Assists in clearing weeds and straw entangled in the cutter and header, keeping the header clean and minimizing malfunctions.

5. Resilience: For fallen crops, a well-designed reel bar can effectively “lift” and straighten the crop, significantly reducing harvest losses.

III. Product Features

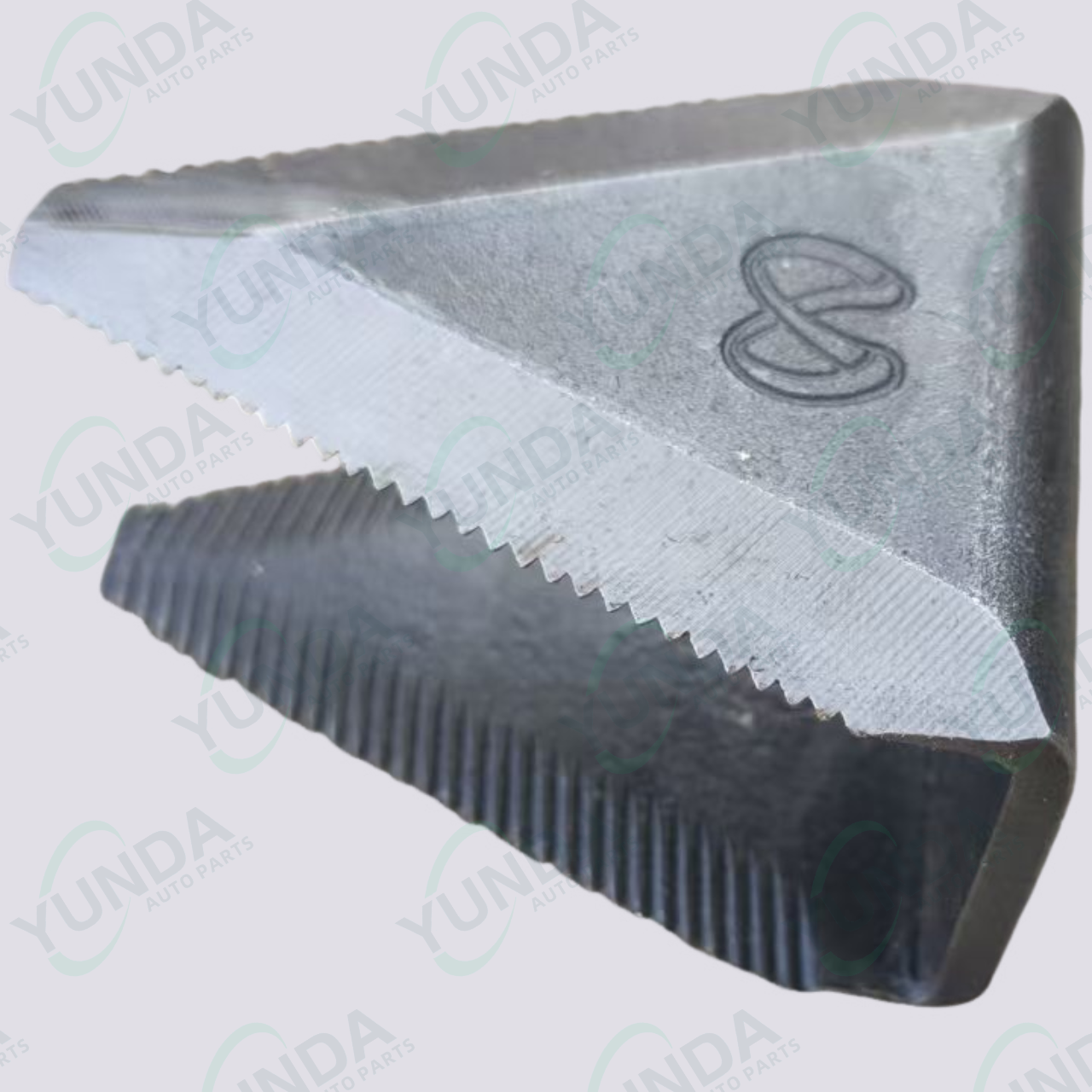

• High Strength and Wear Resistance: The reel bar constantly rubs against crop stems, dust, and gravel during operation, requiring extremely high surface hardness and wear resistance to extend its service life.

• Excellent Toughness: When encountering unexpected obstacles such as rocks and sticks, it requires a certain degree of toughness to prevent instantaneous breakage and protect the overall structure of the reel. • Precise Geometry: The bending angle, length, and mounting dimensions are meticulously designed to perfectly match the specific harvester model and reel, achieving optimal crop support and delivery.

• Lightweight Design: While maintaining strength, modern reel levers tend to be lightweight to reduce the reel’s moment of inertia and lower energy consumption.

IV. Materials and Manufacturing Processes

1. Mainstream Materials:

◦ Alloy Steel: Typically made from high-quality spring steel such as 65Mn (65 manganese steel), this material, after heat treatment, possesses exceptional elasticity and wear resistance, making it the most commonly used and cost-effective material.

◦ Composite Materials: These materials include engineering plastics such as nylon and fiberglass. These reel levers are lightweight, wear-resistant, and gentle on grain pods (such as soybeans), making them particularly suitable for pulses prone to popping.

◦ Rubber/Polyurethane: Mainly used in specially designed reel levers, they offer excellent flexibility and are gentle on crops. 2. Core Processing:

◦ Precision forging/stamping: This forms the basic shape of the lever, ensuring optimal fiber flow and a dense structure.

◦ Heat treatment: This is a critical step in determining lever performance. Through a quenching and tempering process, the lever surface achieves a high hardness (HRC 40-50 or higher) while maintaining sufficient toughness at the core, achieving the ideal “hard exterior, tough interior” performance.

◦ Surface treatment: Some products are painted, dipped, or galvanized to enhance rust and corrosion resistance.

V. Main Types and Applications

• Standard steel lever: The most versatile, suitable for harvesting most grains, including wheat, rice, and corn.

• Soybean-specific lever (composite material): To prevent damage to soybean pods and reduce mud stains, a composite lever is typically used, offering greater flexibility and gentle handling.

• Reinforced/thickened lever: Suitable for harvesting high-density, dense crops (such as high-yield corn and sorghum) or for use in harsh conditions, offering a longer lifespan. • Special design for different crops: The length, spacing and elasticity of the levers will be adjusted accordingly according to the height, density and lodging of the crops.