Description

1. Product Overview

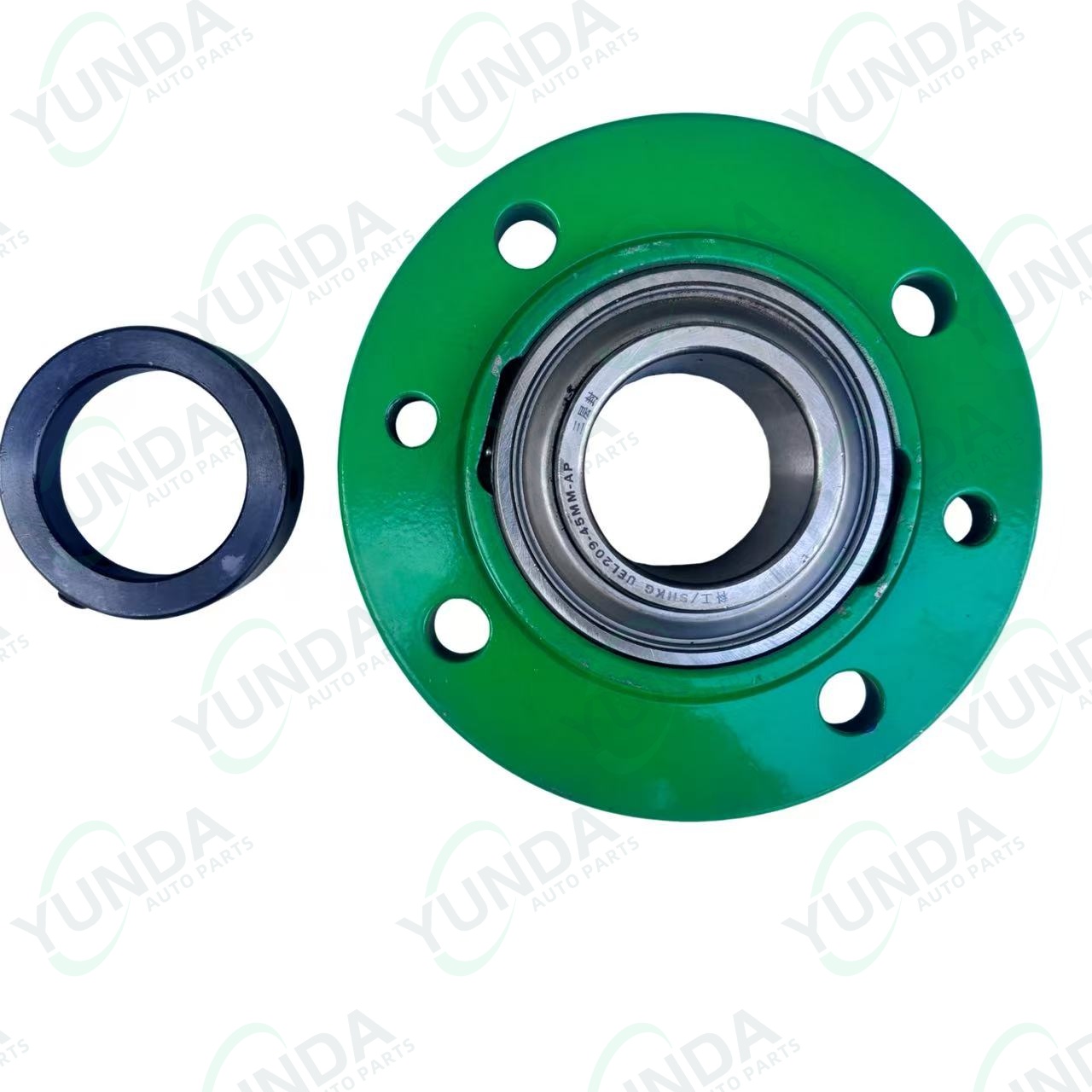

“Flange & Bearing” is commonly referred to as a mounted bearing unit or housing + bearing. It is a pre-assembled, ready-to-install modular assembly consisting of two main components:

• Bearing: Typically a deep groove ball bearing, self-aligning ball bearing, or tapered roller bearing, it is the core component that supports the shaft and ensures its smooth rotation.

• Housing: A cast or stamped housing with a mounting flange. It secures and supports the bearing and installs it in a specific location within the machine.

“6873490” is the specific model number for this assembly, while “Class” may represent its dimensions, performance level (such as accuracy grade, clearance grade), or classification for specific operating conditions.

2. Main Components and Features

a) Bearing

• Type: Based on the model number “6873490,” the bearing inside is likely a deep groove ball bearing. This is the most common and versatile type of mounted bearing.

• Features:

◦ Can accommodate radial loads and certain bidirectional axial loads. ◦ Low friction coefficient and high speed.

◦ Typically equipped with contact or non-contact seals, effectively preventing lubricant leakage and contaminant ingress.

◦ Pre-filled with grease, providing lifetime lubrication under standard operating conditions.

b) Bearing Housing

• Type: As the “Flange” in the name suggests, this is a flanged bearing housing. This means it is secured via circumferential mounting holes, facilitating installation and alignment on flat surfaces.

• Features:

◦ Rigid mounting: The flange mounting provides a secure support that resists overturning moments.

◦ Easy installation: Alignment is simple, and bolts securely fasten to the machine wall or bracket.

◦ Compact design: Space-saving design.

◦ Material: Typically gray cast iron or ductile iron, providing good strength and vibration damping properties; stamped steel plate may also be used for lightly loaded applications.