Description

Definition:

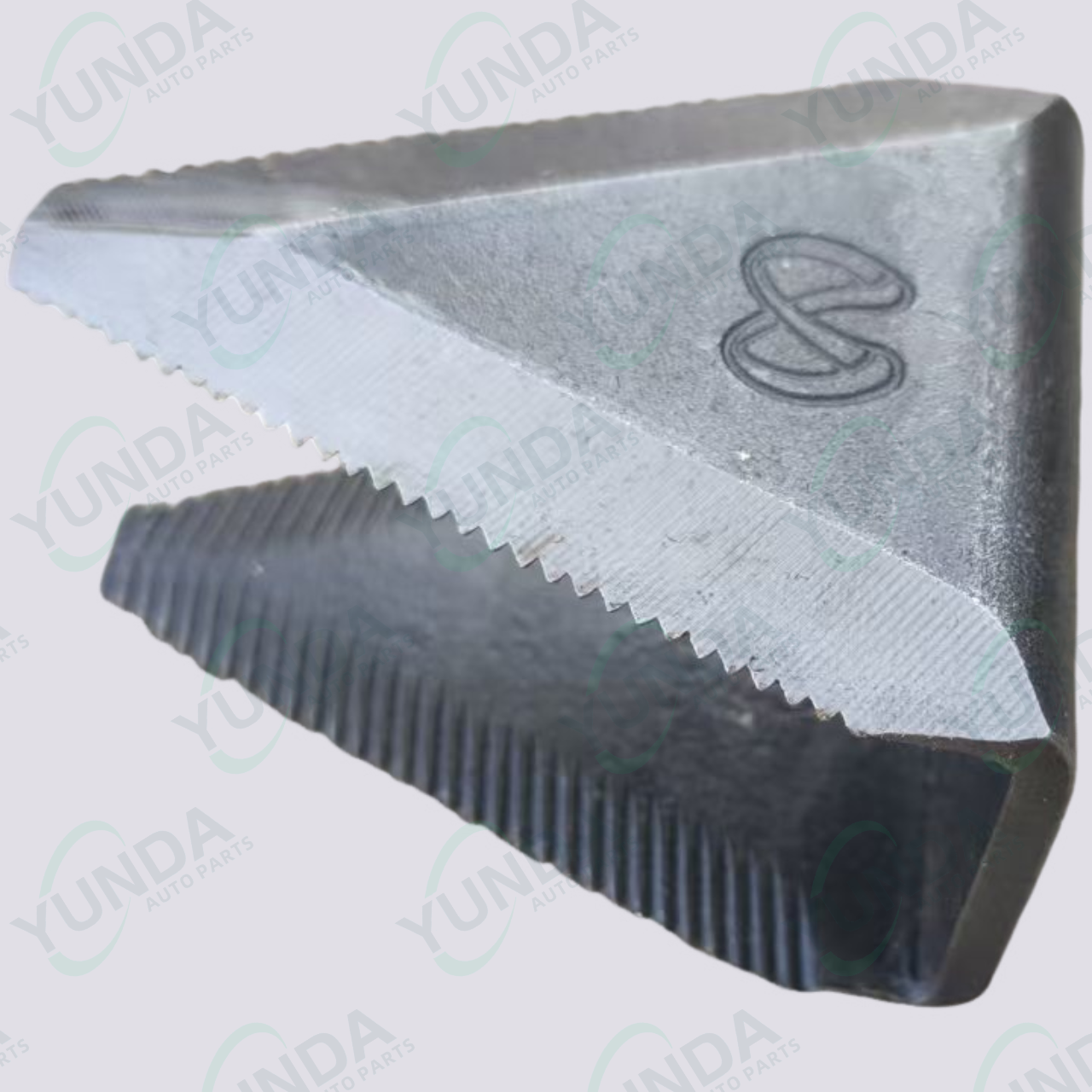

The Splined Hub 0006704010 / 6704011 is a high-strength, precision-machined component designed for the power transmission systems of a Claas combine harvester. It features internal or external splines—a series of ridges or teeth on a shaft that mesh with grooves in a mating part—to create a secure, non-slip connection.

Primary Functions:

-

Torque Transmission: The primary function of the splined hub is to efficiently transmit high levels of rotational torque between two components, such as a shaft and a gear, pulley, or another driveline element. The multiple splines provide a large surface area for force transfer.

-

Secure Connection: It ensures a positive, non-slip connection. Unlike a keyed shaft, the splined design distributes the torque load evenly across all the teeth, preventing localized stress and providing a much more robust and reliable link for high-power applications.

-

Maintaining Phased Alignment: In specific applications, the spline design can ensure that connected components maintain a specific rotational orientation or phased relationship, which is critical for the synchronized timing of various machine functions.

-

Accommodating Movement: Depending on the application, the splined hub can allow for limited axial movement between the connected parts while still transmitting torque. This is essential in assemblies that require slight adjustment or where components may shift slightly during operation.